TY Disassembling Motor Model DIY Kits DC 3-6V Magnet DC Motor Model J24018 for Studying Magnetic Line of Force Educational Practice Learning Kit

Product Details

1.Introduction:

This is a simple permanent magnet DC motor model to demonstrate the DC electric motor working principle. It can be taken apart and reassembled when powered with DC 3-6V voltage. It will rotate like a real electric motor ideal for school scientific projects or physics teaching.

2.Features:

Easy installation;

Rare accessories;

Experimental display;

Obvious effect;

Wide applicability.

3.Parameter:

Product name:Electric Motor model DIY Kit;

Model:J24018;

Working voltage:DC 3.0V-6.0V;

Material:plastic + metal;

Usage: Study magnetic lines of force;

Magnet size:22*20*20mm(0.86*0.79*0.79 inch);

Magnetic flux density:>=72mT;

Operating Temperature:-20℃~70℃;

Operating Humidity:5%-90%RH;

Installed size:14*9*10cm(5.51*3.54*3.94 inch).

4.Function:

Manual installation allows the user to understand the main structure of the electric motor.

Verify the relationship between rotor rotation and current direction and magnetic lines.

Master the principle of motor operation.

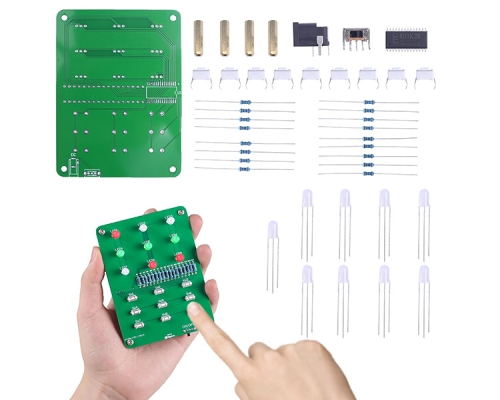

5. Component listing

Items in the package:

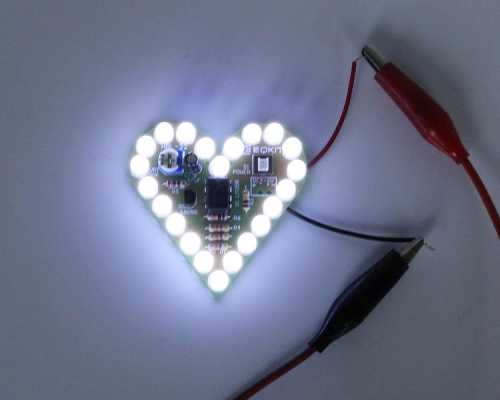

Finished product after installation:

6.Using steps:

Finish install as following install manual;

Connect to DC 3.0V-6.0V at two cable;

Observe the work situation.

7.Application:

Education;

School;

Manual DIY;

Gift.

8.Note:

DC electric motor experiment:input 3V - 6V DC through wires and terminals, the coil will rotating, and speed up when voltage step up.

To avoid short circuit, two electric brushes never touch the commutator segment.

Its working voltage is DC 3.0V-6.0V. And DC12V is not recommended.

9.Installation Steps:

- Step1: Install magnet bracket on the plastic seat and fixed by M3 screw and M3 nut.

- Step2: Install 1pc rotor bracket at first and fixed by M3 screw and M3 nut.

- Step3: Install another rotor bracket and rotor/commutator/armature coil and fixed by M3 screw and M3 nut.

- Step4: Install pulley on the rotor.

- Step5: Bend the angle of the electric brush

- Step6: Install electric brush and fixed by M3 screw and M3 nut.

- Step7: Install Red+Black Terminal and fixed by M4 screw and M4 nut.

- Step8: Install Permanent Magnet.

- Step9: When you finish the motor assembly, please turn the rotor bracket to let the gap middle between the 2 brushes.

- Step10: Connect to the cable on the terminal and then connect it to DC 3.0V-6.0V power to do a test.

( Please NOTE:

1. To avoid the short circuit, two electric brushes never touch the commutator segment.

2. Its working voltage is DC 3.0V-6.0V. And DC12V is not recommended. )